Infrastructure gaskets are vital components used in various civil engineering and infrastructure projects to create watertight seals, prevent leaks, and ensure the integrity and longevity of structures and systems. These gaskets are designed to withstand environmental factors, structural movement, and dynamic loads while providing reliable sealing performance in a wide range of applications. Here’s an extensive exploration of infrastructure gaskets, including their types, functions, materials, installation methods, and applications:

1. Types of Infrastructure Gaskets:

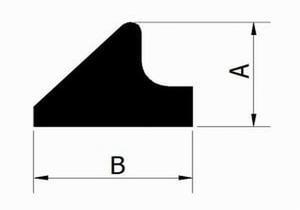

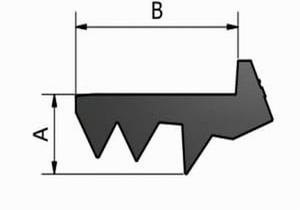

- Pipe Gaskets: Pipe gaskets are used to create a seal between pipe joints in water and wastewater systems, sewer networks, and industrial pipelines. They are available in various profiles, including rubber ring gaskets, compression gaskets, and spiral-wound gaskets, to accommodate different pipe materials, sizes, and operating conditions.

- Manhole Gaskets: Manhole gaskets, also known as frame seals or chimney seals, are installed between manhole covers and frames to prevent infiltration of water, debris, and gases into underground utility structures. These gaskets are typically made from rubber or elastomeric materials and provide a flexible, watertight seal in circular or rectangular openings.

- Expansion Joint Gaskets: Expansion joint gaskets, also known as movement joint seals or bellows, are used to accommodate movement, thermal expansion, and vibration in infrastructure systems such as bridges, highways, and buildings. They are available in various configurations, including rubber expansion joints, metal bellows, and fabric-reinforced joints, to suit different structural requirements.

- Concrete Gaskets: Concrete gaskets, also known as concrete joint seals or waterstops, are installed in concrete structures such as dams, reservoirs, tunnels, and basements to prevent water infiltration and leakage through construction joints, expansion joints, and settlement cracks. These gaskets may be made from rubber, PVC, or bentonite materials and provide durable, long-lasting sealing performance in harsh environments.

2. Functions of Infrastructure Gaskets:

- Watertightness: The primary function of infrastructure gaskets is to maintain watertightness and prevent the ingress of water, sewage, or other fluids into underground and aboveground structures. Watertight seals are essential for preventing leaks, minimizing water loss, and protecting against structural deterioration and environmental contamination.

- Chemical Resistance: Gaskets used in industrial applications such as chemical processing plants, wastewater treatment facilities, and storage tanks must withstand exposure to corrosive chemicals, acids, and solvents. Chemical-resistant gaskets provide a barrier against chemical attack, ensuring the safety and integrity of infrastructure systems.

- Load Transfer: Gaskets play a crucial role in transferring loads, forces, and movements between structural components, particularly in bridge expansion joints, pavement joints, and building joints. They help distribute loads evenly, reduce stress concentrations, and prevent premature failure or damage to infrastructure elements.

- Seismic and Thermal Protection: In seismic-prone regions, infrastructure gaskets help mitigate the effects of earthquakes by accommodating movement and reducing structural damage. Seismic expansion joints and isolation gaskets provide flexibility and damping properties to absorb seismic energy and protect buildings, bridges, and pipelines from displacement and collapse.

3. Materials for Infrastructure Gaskets:

- Rubber: Rubber gaskets, including EPDM, neoprene, nitrile, and silicone rubber, offer excellent flexibility, resilience, and weather resistance. Rubber seals are suitable for a wide range of applications and can withstand exposure to UV radiation, ozone, and harsh environmental conditions.

- Plastics: Plastic gaskets, such as PVC, polyethylene (PE), and polypropylene (PP), offer chemical resistance, low friction, and dimensional stability. Plastic seals are used in applications where compatibility with aggressive fluids or elevated temperatures is required, such as chemical containment systems and wastewater treatment plants.

- Metal: Metal gaskets, including stainless steel, aluminum, and copper alloys, provide high strength, durability, and resistance to corrosion. Metal seals are often used in high-pressure and high-temperature applications, such as pipeline flanges, heat exchangers, and pressure vessels.

- Composite Materials: Composite gaskets combine the properties of multiple materials, such as rubber, fabric, and metal, to achieve specific performance requirements. Composite seals offer enhanced durability, flexibility, and sealing performance in demanding applications such as bridge expansion joints and tunnel seals.

4. Installation Methods:

- Compression Fitting: Many infrastructure gaskets are installed by compressing them between mating surfaces, such as pipe flanges, concrete joints, and manhole frames. Proper compression fitting ensures uniform contact and sealing pressure along the entire length of the gasket, preventing leaks and ensuring long-term performance.

- Adhesive Bonding: Some gaskets are equipped with adhesive backing for easy installation on clean, dry surfaces. Adhesive bonding provides a secure and permanent attachment, ensuring a watertight seal between mating surfaces without the need for mechanical fasteners.

- Mechanical Fastening: In applications where high mechanical strength is required, gaskets may be installed using mechanical fasteners such as bolts, screws, or clamps. Mechanical fastening provides additional stability and resistance to vibration, movement, and dynamic loads.

5. Applications of Infrastructure Gaskets:

- Water and Wastewater Systems: Infrastructure gaskets are widely used in water supply, sewage, and drainage systems to ensure watertight connections and prevent leaks. Pipe gaskets, manhole gaskets, and concrete joint seals are critical components in water treatment plants, sewer networks, and stormwater management systems.

- Transportation Infrastructure: Gaskets are employed in transportation infrastructure such as bridges, highways, tunnels, and railways to accommodate movement, expansion, and contraction. Expansion joint gaskets, pavement seals, and tunnel seals help maintain structural integrity and safety in infrastructure systems subjected to traffic loads, temperature variations, and seismic activity.

- Building Construction: Infrastructure gaskets are used in building construction and renovation projects to create watertight seals in concrete structures, expansion joints, and curtain wall systems. Concrete joint seals, expansion joint gaskets, and window gaskets contribute to the durability, energy efficiency, and sustainability of buildings.

- Industrial Facilities: Gaskets play a crucial role in industrial facilities such as chemical plants, refineries, and power plants to prevent leaks, spills, and environmental contamination. Chemical-resistant gaskets, flange gaskets, and expansion joint seals ensure the safe and reliable operation of equipment and piping systems in harsh industrial environments.

In summary, infrastructure rubber gaskets are essential components in civil engineering and infrastructure projects, providing watertightness, structural integrity, and environmental protection in water and wastewater systems, transportation infrastructure, building construction, and industrial facilities. With a variety of types, materials, and applications, these gaskets contribute to the safety, reliability, and sustainability of infrastructure systems worldwide.