EPDM rubber seals are widely recognized for their exceptional durability, versatility, and resistance to various environmental factors, making them indispensable components in numerous industrial, automotive, construction, and residential applications. EPDM rubber is a synthetic elastomer known for its excellent weather resistance, thermal stability, and insulating properties, making it ideal for outdoor and indoor use alike.

One of the most prominent features of EPDM rubber seals is their remarkable ability to withstand prolonged exposure to harsh weather conditions, including extreme temperatures, UV radiation, ozone, and moisture. Unlike many other elastomers, EPDM rubber remains resilient and flexible over a wide temperature range, from -50°C to 150°C (-58°F to 302°F), ensuring consistent performance in both hot and cold environments. This thermal stability makes EPDM seals suitable for applications ranging from automotive weatherstripping to HVAC systems and outdoor enclosures.

EPDM rubber seals also boast excellent resistance to chemical exposure, including acids, alkalis, solvents, and oxidizing agents, further enhancing their longevity and reliability in demanding environments. This chemical resistance extends the service life of EPDM seals, making them suitable for applications in chemical processing plants, laboratories, and industrial machinery where exposure to corrosive substances is common.

Furthermore, EPDM rubber exhibits superior electrical insulation properties, making it an ideal material for sealing electrical enclosures, wiring harnesses, and connectors. Its dielectric strength and resistance to electrical conductivity help prevent moisture ingress and maintain the integrity of electrical systems, ensuring optimal performance and safety.

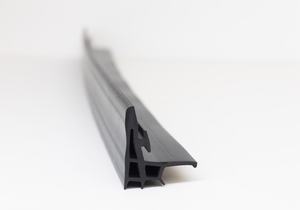

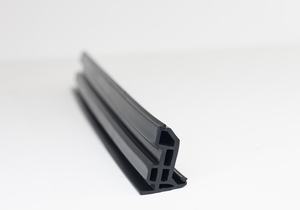

In addition to its resilience and protective properties, EPDM rubber seals are also known for their ease of installation and versatility. Available in various shapes, sizes, and configurations, including extruded profiles, O-rings, gaskets, and custom-molded parts, EPDM seals can be tailored to fit specific applications and design requirements with precision. They can be easily cut, bonded, or formed to create a seamless seal, providing effective protection against dust, debris, noise, and vibration.

EPDM rubber seals find extensive use in automotive manufacturing, where they are employed in door seals, window seals, trunk seals, and under-the-hood applications to prevent water intrusion, reduce noise, and enhance passenger comfort. They are also widely utilized in construction applications, such as roofing systems, window glazing, and expansion joints, where they provide durable weatherproofing and thermal insulation.

Moreover, EPDM rubber are valued for their eco-friendly properties, as they are made from non-toxic materials and are recyclable, contributing to sustainability efforts and environmental compliance in various industries.

In conclusion, EPDM rubber gaskets offer a combination of resilience, versatility, and reliability that make them indispensable components in a wide range of applications. From automotive and construction to industrial and electrical systems, EPDM seals provide durable protection against environmental factors, chemicals, and electrical hazards, ensuring long-term performance and peace of mind for engineers, designers, and end-users alike.