GRP pipe seals are essential components used in the installation and maintenance of GRP pipelines to ensure watertightness, structural integrity, and longevity. These seals are specifically designed to create a secure and reliable seal between pipe joints, preventing leaks, infiltration, and corrosion. Here’s a detailed exploration of GRP pipe seals, including their types, functions, materials, installation methods, and applications:

1. Types of GRP Pipe Seals:

- Rubber Ring Seals: Rubber ring seals, also known as elastomeric seals, are commonly used in GRP pipe joints to provide a flexible and watertight seal. These seals are typically made from materials such as EPDM (ethylene propylene diene monomer) rubber, neoprene, or nitrile rubber and are designed to fit securely within the socket or spigot ends of GRP pipes.

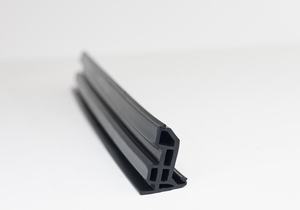

- Compression Seals: Compression seals, also known as mastic seals or compression gaskets, are preformed profiles made from rubber, thermoplastic elastomers (TPE), or other flexible materials. These seals are inserted into the joint cavity before assembly and are compressed between pipe sections, forming a tight seal that prevents water infiltration and soil migration.

- Threaded Seals: Threaded seals utilize threaded connections or couplings to join GRP pipes together securely. These seals often incorporate elastomeric gaskets or O-rings to provide a seal between the threaded components, ensuring leak-free performance in pressurized pipeline systems.

2. Functions of GRP Pipe Seals:

- Watertightness: The primary function of GRP pipe seals is to maintain watertightness and prevent the ingress and egress of water, sewage, or other fluids through pipe joints. Watertight seals are essential for preventing leaks, minimizing water loss, and ensuring the efficient operation of water and wastewater systems.

- Structural Integrity: GRP pipe seals contribute to the structural stability and longevity of pipelines by providing uniform support, load transfer, and resistance to external forces such as soil movement, traffic loads, and seismic activity. Properly sealed joints help maintain pipeline alignment and prevent joint displacement or failure.

- Corrosion Protection: GRP pipe seals help protect against corrosion by preventing the infiltration of moisture and corrosive substances into the pipe joints. This is particularly important in corrosive environments such as wastewater treatment plants, industrial facilities, and marine applications.

- Seismic and Thermal Expansion Control: GRP pipe seals accommodate thermal expansion and contraction as well as seismic movement, helping to reduce stress on the pipeline and prevent damage or failure during temperature fluctuations or seismic events.

3. Materials for GRP Pipe Seals:

- EPDM Rubber: EPDM rubber is a popular choice for GRP pipe seals due to its excellent weather resistance, flexibility, and durability. EPDM seals offer superior performance in outdoor environments and are resistant to ozone, UV radiation, and chemical degradation.

- Neoprene Rubber: Neoprene rubber provides good resistance to oil, fuel, and weathering, making it suitable for use in pipelines exposed to petroleum-based fluids or outdoor conditions. Neoprene seals offer excellent compression set resistance and sealing performance.

- Nitrile Rubber: Nitrile rubber, also known as Buna-N or NBR, is highly resistant to oils, fuels, solvents, and hydraulic fluids. Nitrile seals are commonly used in industrial applications where resistance to hydrocarbons and chemicals is required.

- TPE (Thermoplastic Elastomers): TPE seals combine the flexibility and resilience of rubber with the processability and recyclability of thermoplastics. TPE materials offer excellent compression set resistance, chemical resistance, and low-temperature flexibility.

4. Installation Methods:

- Socket and Spigot Joints: GRP pipe seals are typically installed in socket and spigot joints, where the spigot end of one pipe is inserted into the socket end of another pipe. Rubber ring seals or compression seals are placed within the joint cavity before assembly, ensuring a secure and watertight connection.

- Compression Couplings: Compression couplings incorporate compression seals or gaskets to join GRP pipes together without the need for adhesive or solvent bonding. These couplings are tightened to compress the seals and create a leak-free connection between pipe sections.

- Threaded Connections: Threaded seals are used in threaded connections or couplings to join GRP pipes together securely. Elastomeric gaskets or O-rings are placed between the threaded components to provide a seal, and the threads are tightened to create a leak-free joint.

5. Applications of GRP Pipe Seals:

- Water and Wastewater Systems: GRP pipe seals are widely used in water supply, sewage, and drainage systems to ensure watertight connections and prevent leaks. They are suitable for both aboveground and underground installations, including potable water pipelines, sewer lines, and stormwater drainage systems.

- Industrial Pipelines: GRP pipe seals are employed in industrial applications such as chemical processing plants, power generation facilities, and oil and gas refineries to transport corrosive fluids and chemicals safely and efficiently.

- Marine and Offshore Structures: GRP pipe seals are utilized in marine and offshore applications such as shipbuilding, offshore platforms, and coastal infrastructure to withstand harsh environmental conditions, including saltwater exposure, wave action, and temperature variations.

- Infrastructure Rehabilitation: GRP pipe seals are used in rehabilitation and renovation projects to repair and upgrade aging or damaged pipelines without the need for extensive excavation. Compression seals and compression couplings facilitate quick and efficient repairs, minimizing downtime and disruption to services.

In summary, GRP pipe gaskets are essential components in GRP pipeline systems, providing watertightness, structural integrity, and corrosion protection. Their versatility, durability, and resistance to environmental factors make them well-suited for a wide range of applications in water and wastewater systems, industrial facilities, marine structures, and infrastructure projects.