Aluminum rubber, often referred to as aluminum elastomer or aluminum-filled rubber, is a composite material that combines the properties of aluminum with those of rubber. This innovative material typically consists of a rubber matrix, such as silicone or fluorosilicone, filled with finely powdered aluminum particles.

The combination of rubber and aluminum offers unique properties and advantages that make it suitable for a variety of applications across different industries:

- Lightweight yet Durable: Aluminum rubber maintains the lightweight characteristic of rubber while incorporating the strength and durability of aluminum. This makes it ideal for applications where weight reduction is critical, such as in aerospace and automotive components.

- Conductive Properties: The presence of aluminum particles within the rubber matrix imparts electrical conductivity to the material. This makes aluminum rubber suitable for use in applications where electrical grounding or shielding is necessary, such as in electromagnetic interference (EMI) shielding in electronic devices and equipment.

- Thermal Conductivity: Aluminum rubber exhibits enhanced thermal conductivity compared to conventional rubber materials. This property makes it suitable for applications requiring efficient heat dissipation, such as in thermal interface materials for electronic devices and heat exchangers.

- Vibration Damping: The elastomeric nature of the rubber matrix provides excellent vibration damping properties, which is beneficial in applications where vibration isolation or damping is required, such as in automotive suspension systems and machinery mounts.

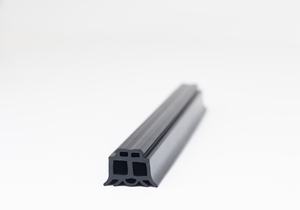

- Sealing and Gasketing: Aluminum rubber can be formed into seals and gaskets with excellent resilience and sealing properties. It is commonly used in aerospace, automotive, and industrial applications to create reliable seals that withstand harsh operating conditions, including temperature variations and exposure to fluids and gases.

- Corrosion Resistance: The presence of aluminum in the rubber matrix enhances the material’s resistance to corrosion, making it suitable for applications where exposure to corrosive environments is a concern, such as marine and chemical processing industries.

- Machinability and Formability: Despite the presence of aluminum particles, aluminum rubber can still be machined and formed using conventional techniques, allowing for the fabrication of complex shapes and components tailored to specific application requirements.

- Cost-Effectiveness: While aluminum rubber may be more expensive than traditional rubber materials due to the inclusion of aluminum particles, its unique combination of properties often results in cost savings over the lifecycle of the product, particularly in applications where durability, performance, and reliability are crucial factors.

Aluminum gaskets represents a versatile and high-performance material that bridges the gap between rubber and metal, offering a wide range of benefits across various industrial sectors, including aerospace, automotive, electronics, and manufacturing. Its unique combination of properties makes it a compelling choice for engineers and designers seeking innovative solutions to meet the demands of modern applications.