Concrete pipe seals are essential components used in the construction and maintenance of concrete pipelines to ensure watertightness, structural integrity, and longevity. These seals come in various forms and materials, each tailored to specific pipe dimensions, installation methods, and environmental conditions. Here’s a comprehensive overview of concrete pipe seals, including their types, functions, materials, and applications:

1. Types of Concrete Pipe Seals:

- Rubber Gaskets: Rubber gaskets are one of the most common types of seals used in concrete pipe joints. They are typically made from materials such as EPDM (ethylene propylene diene monomer), neoprene, or nitrile rubber and are designed to provide a flexible, watertight seal between pipe sections.

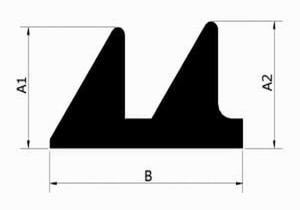

- Compression Seals: Compression seals, also known as mastic seals or compression gaskets, are preformed rubber or thermoplastic profiles inserted into the joint cavity before the concrete is poured. They are compressed between pipe sections during installation, forming a tight seal that prevents water infiltration and soil migration.

- Lubricated Rubber Rings: Lubricated rubber rings consist of a rubber gasket coated with a lubricant to facilitate installation. The lubricant reduces friction during joint assembly, allowing for easier insertion and alignment of pipe sections while maintaining a secure seal.

- Mechanical Joints: Mechanical joints, such as tongue-and-groove or spigot-and-socket joints, utilize interlocking features to provide both structural support and sealing. These joints often incorporate rubber gaskets or compression seals to enhance watertightness and prevent joint displacement.

2. Functions of Concrete Pipe Seals:

- Watertightness: The primary function of concrete pipe seals is to prevent the ingress and egress of water, sewage, or other fluids through pipe joints. Watertight seals are essential for maintaining hydraulic efficiency, preventing leaks, and minimizing the risk of infrastructure damage or environmental contamination.

- Structural Integrity: Concrete pipe seals contribute to the structural stability and longevity of pipelines by providing uniform support, load transfer, and resistance to external forces, including soil movement, traffic loads, and seismic activity.

- Alignment and Joint Stability: Seals help to align and stabilize concrete pipe joints, ensuring proper fit and alignment between pipe sections. This alignment is critical for maintaining hydraulic capacity, minimizing flow restrictions, and preventing joint displacement or misalignment.

- Corrosion Protection: Certain types of concrete pipe seals, particularly those made from corrosion-resistant materials like EPDM or neoprene rubber, provide a protective barrier against corrosion caused by chemical exposure, abrasion, or galvanic reactions.

3. Materials for Concrete Pipe Seals:

- EPDM Rubber: EPDM rubber is highly resistant to weathering, ozone, UV radiation, and chemical degradation, making it an excellent choice for outdoor applications and environments with exposure to harsh conditions.

- Neoprene Rubber: Neoprene rubber offers excellent oil resistance, flexibility, and durability, making it suitable for applications involving exposure to petroleum-based fluids or hydrocarbons.

- Nitrile Rubber: Nitrile rubber, also known as Buna-N or NBR, provides superior resistance to oils, fuels, solvents, and hydraulic fluids, making it ideal for sealing applications in industrial pipelines and wastewater systems.

- Thermoplastic Elastomers (TPE): Thermoplastic elastomers combine the flexibility and resilience of rubber with the processability and recyclability of thermoplastics. TPE seals offer excellent compression set resistance, chemical resistance, and low-temperature flexibility.

4. Applications of Concrete Pipe Seals:

- Sanitary Sewer Systems: Concrete pipe seals are widely used in sanitary sewer systems to prevent leaks, infiltration, and exfiltration of sewage, ensuring public health and environmental protection.

- Stormwater Drainage: Concrete pipe seals play a crucial role in stormwater drainage systems by preventing water loss, soil erosion, and flooding caused by inadequate sealing at pipe joints.

- Culverts and Bridges: Concrete culverts and bridge structures rely on watertight seals to maintain hydraulic efficiency, prevent scouring, and ensure the structural integrity of transportation infrastructure.

- Water Supply Networks: Concrete pipe seals are utilized in water supply networks to transport potable water, irrigation water, or industrial fluids, requiring reliable sealing to prevent contamination and water loss.

- Trenchless Pipeline Rehabilitation: Concrete pipe seals are often employed in trenchless rehabilitation methods, such as pipe lining or pipe bursting, to repair aging or damaged pipelines without excavation, minimizing disruption to the surrounding environment.

In summary, concrete pipe gaskets are indispensable components of concrete pipeline systems, providing watertightness, structural integrity, and longevity. By selecting the appropriate type and material of seal for specific application requirements, engineers and contractors can ensure the reliable performance and longevity of concrete pipelines in diverse infrastructure projects.